For this assignment we have taken an object modeling with clay. First it will scan using a 3D scanning machine. Then export it as an object in *iges format, to a CAD software (in this case in Rhino) for editing. Finally generarmos the * stl file to open it in the driver of the machine and send it to print .

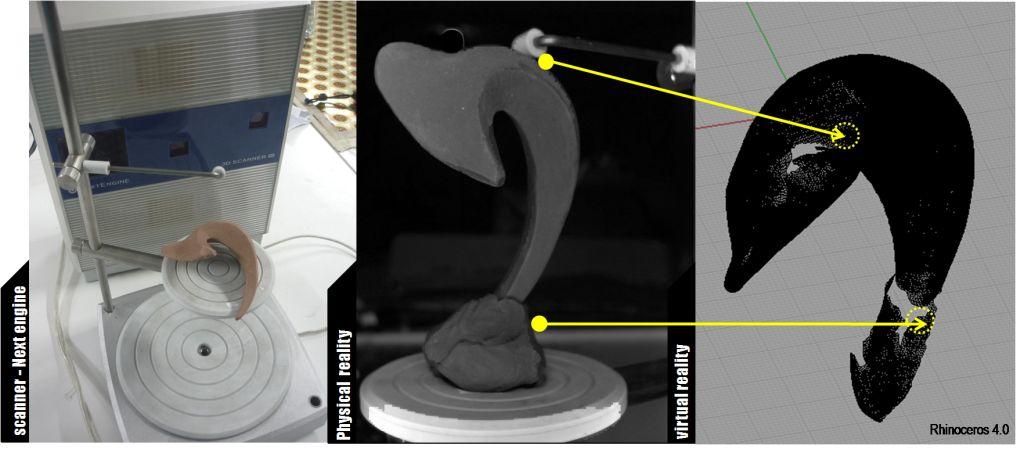

SCANNING: 3d Lasser Scann

The 3D scanning machine can collect all the information fisical reality of our object(360°). However depends on the geometry of it and as we locate the position to obtain the complete record from bits of the object

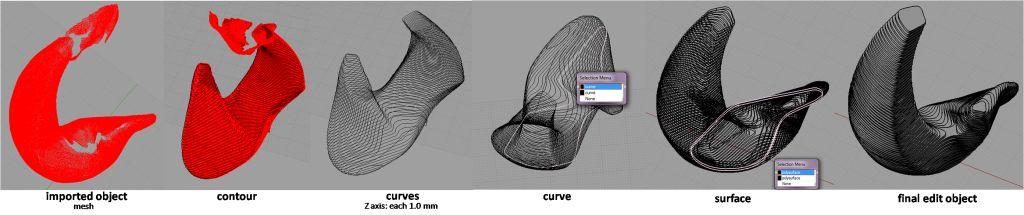

EDITION:We´ll modify the geometry. So we generate a set of surfaces from the application of contour command, that way we are left only with the necessities of geometry.

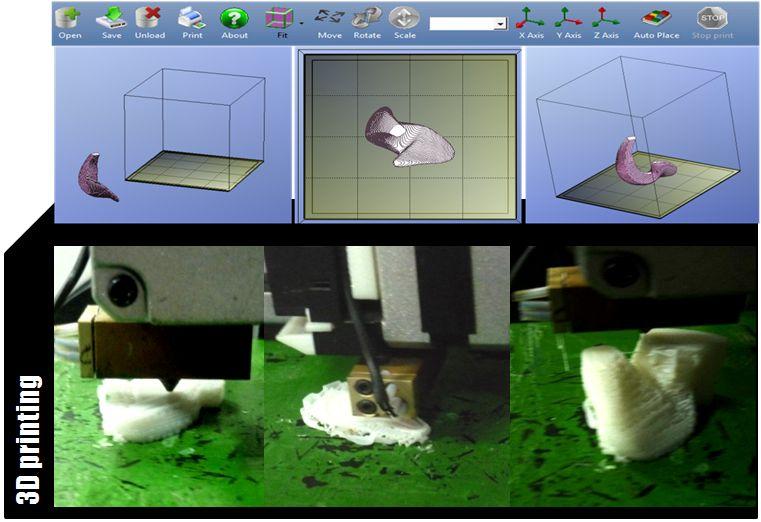

PRINTING: Up 3d Printer machine

- import the file in * stl format.

- position the object in the working area (scale it if necessary)

- check the amount of material

- calibrate the machine (temperature 200 ° C),

- send to print the object.

- remove the scraps of the object with the tools.

Final comments: Scanning process requires a PC with good processor. If we want our object has a high resolution, scan time will be longer. For the 3D printing process: it is important to generate a good definition of the object in CAD (edition process), if we want the finished print is accurate